Membrane Changes Explained: A Comprehensive Overview to Their Advantages

Membrane layer switches over represent a sophisticated and versatile option for producing user interfaces throughout a range of industries. As markets progressively look for reputable and effective control interfaces, recognizing the certain benefits and applications of membrane switches comes to be necessary.

What Are Membrane Buttons?

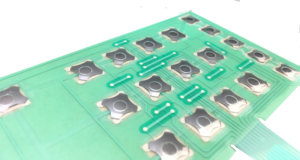

When stress is used to the membrane layer switch, the layers make contact, completing an electrical circuit. This straightforward mechanism permits a large variety of applications, from consumer electronics to commercial machinery. Membrane layer switches are usually designed to be resistant and waterproof to dirt and contaminants, making them ideal for settings where durability is essential.

Additionally, the versatility of the materials used in membrane changes assists in cutting-edge layouts that can adapt different forms and measurements. This versatility adds to their appeal in diverse areas, consisting of clinical gadgets, vehicle controls, and home appliances. Generally, membrane layer switches over stand for a critical element in modern interface innovation, connecting the gap between individuals and digital systems.

Trick Advantages of Membrane Buttons

Amongst the myriad of user interface options available, membrane layer switches over attract attention for their one-of-a-kind mix of benefits. Among the main benefits is their portable and lightweight design, which enables assimilation right into a large range of tools without adding considerable bulk. This is specifically beneficial in applications where space is restricted.

Furthermore, membrane layer switches deal durability and resistance to ecological aspects. They are commonly created with materials that can withstand dampness, dust, and numerous chemicals, making them ideal for extreme conditions. This longevity contributes to a longer life expectancy contrasted to typical mechanical buttons.

Another considerable advantage is the flexibility in personalization. Membrane layer switches can be published with various graphics, shades, and structures, enabling tailored layouts that satisfy details branding or functional needs. This versatility expands to the number of layers and circuit alternatives, providing engineers with several arrangements.

Furthermore, the responsive responses offered by some membrane layer switches improves customer experience, making them much more user-friendly to run. The ease of cleansing and upkeep further solidifies membrane switches as a functional choice in both consumer and industrial applications. Generally, these key advantages make them a favored remedy for many designers and producers

Applications in Different Industries

Exactly how do membrane layer buttons find their place across diverse industries? Their flexibility and performance make them indispensable components in markets ranging from healthcare to consumer electronics. In clinical tools, membrane layer switches are utilized for their ease of cleansing and resistance to contamination, guaranteeing hygiene in environments where sterility is essential.

In the customer electronic devices sector, these buttons offer smooth, straightforward user interfaces that improve product visual appeals while maintaining toughness versus deterioration. Automotive applications take advantage of membrane switches over too, where they are made use of in control panels and control panels, providing dependable performance in challenging conditions.

In addition, commercial machinery employs membrane layer buttons for control board due view it to their robustness, capacity to stand up to severe atmospheres, and customizable layouts that satisfy particular functional requirements. The food market leverages membrane buttons for their simplicity of use and resistance to spills, making certain operational efficiency in busy settings.

Ultimately, the versatility of membrane changes across these varied applications emphasizes their important role in contemporary innovation, enhancing customer interaction while fulfilling industry-specific needs. Their continued advancement guarantees further combination right into arising fields and innovative products.

Layout and Personalization Choices

The layout and personalization alternatives available for membrane layer buttons are critical for tailoring user interfaces to fulfill specific individual needs and visual choices. These switches can be created in numerous shapes, sizes, and formats, enabling seamless combination right into varied applications. The flexibility in layout indicates that manufacturers can produce one-of-a-kind interfaces that improve use and keep brand identity.

Customized colors, structures, and graphics can be related to the surface of the membrane layer button, giving a chance for branding and individual interaction. Furthermore, backlighting options, such as LED illumination, can be incorporated to improve exposure in low-light conditions, therefore boosting capability.

Useful components can additionally be tailored, consisting of tactile feedback and actuation pressure, which can be readjusted to match various customer communications. The selection of products, such as polyester or polycarbonate, enables variants in longevity and environmental resistance, dealing with the specific needs of various sectors.

Ultimately, the extensive layout and modification capacities of membrane buttons make it possible for firms to produce straightforward and aesthetically enticing user interfaces, ensuring that their products fulfill both practical and aesthetic demands successfully. Membrane Switches.

Considerations for Implementation

Carrying out membrane layer switches needs mindful consideration of different variables to guarantee optimum functionality and individual experience. Aspects such as direct exposure to moisture, extreme temperature levels, and chemical materials can significantly affect the button's efficiency and longevity.

Another crucial facet is the button's layout and format. Guaranteeing that the tactile comments and actuation pressure line up with customer assumptions boosts useful source use. Conducting individual testing can supply beneficial understandings right into the optimal design.

Additionally, compatibility with electronic elements need to be evaluated. The switch's circuitry should align with the overall system style, making certain dependable signal transmission and reducing interference.

Moreover, manufacturing approaches and expenses ought to be assessed. The option between customized designs and standard versions can affect both budget and lead time.

Finally, consider repair and maintenance. Membrane buttons might require click here for more specific cleansing and care procedures to keep their look and functionality with time. By resolving these considerations, organizations can implement membrane layer switches that fulfill their operational needs while providing a favorable individual experience.

Conclusion

In final thought, membrane switches stand for a sturdy and flexible control interface ideal for a variety of applications throughout multiple sectors. Their compact layout, resistance to environmental factors, and adjustable features improve user experience while meeting particular branding demands. As innovation remains to develop, the importance of membrane buttons in contemporary tools remains substantial, offering both performance and visual appeal. Future advancements will likely additionally increase their applications and effectiveness in different settings.

Membrane changes stand for a versatile and advanced option for creating user interfaces across a variety of industries.Recognizing the basic parts of modern electronic interfaces, membrane switches are a type of user interface gadget that consist of versatile, thin layers of material. In general, membrane switches represent a crucial element in modern user interface modern technology, linking the gap between individuals and electronic systems.

Among the myriad of customer interface alternatives readily available, membrane layer switches stand out for their one-of-a-kind combination of benefits.The style and personalization options offered for membrane buttons are essential for customizing user interfaces to fulfill specific customer requirements and aesthetic preferences.